How to Choose the Right Automotive Wheel Weights for Your Vehicle

Introduction

Automotive Wheel Weights are small, precisely measured metal or composite devices mounted on vehicle rims that balance irregularities in the tire-wheel assembly to ensure smooth, balanced rotation.

While wheel weights may seem like an inconspicuous part of your vehicle, they play a vital role in maintaining a smooth and balanced ride. Now let’s delve into the world of wheel weights.

Understanding Wheel Weights

What Are Wheel Weights?

Unbalanced tire-wheel assembly can occur due to manufacturing differences, uneven tire wear, or the addition of aftermarket parts. Need more information on why balancing your tires is so important? We got you.

When wheels are unbalanced, vibrations occur, causing uneven tire wear, reduced fuel efficiency, impaired handling and an uncomfortable ride.

Wheel weights serve the following main purposes:

- Balance: Wheel weight allows the tire-wheel assembly to rotate evenly by strategically adding or subtracting weight. This balance minimizes vibration, improves ride quality and enhances vehicle performance.

- Stability: Balanced wheels improve stability and traction, especially at high speeds. It ensures the best controllability and operability, reduces the risk of accidents and improves overall safety.

Characteristics of Wheel Weights

Wheel weights typically appear as small, rectangular or curved metallic pieces. They are often coated with a corrosion-resistant material, such as zinc or lead-free plastic, to protect against environmental elements.

They are attached to the wheel’s rim, either on the inner or outer surface. They are strategically placed to offset imbalances caused by tire or wheel assembly irregularities.

Types of Wheel Weights

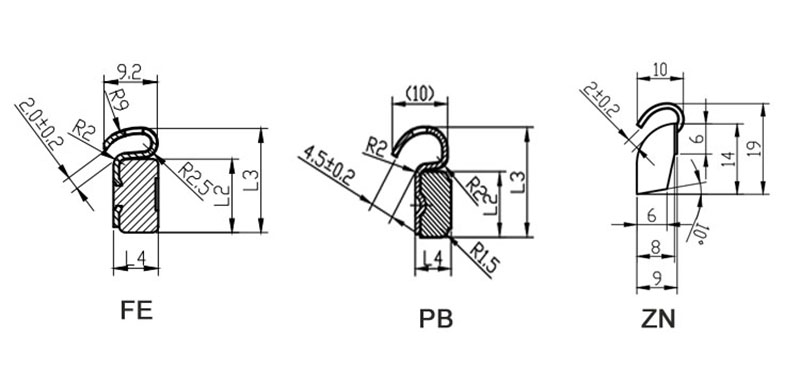

Clip-On wheel Weights:These wheel weights feature a clamp-like design that securely attaches to the rim. They are commonly used in steel wheels and can be easily installed or removed without damaging the wheel finish. Clip-on wheel weights are available in various sizes and are widely used in professional tire shops.

Stick on wheel weights:These stick on wheel weights are backed with strong adhesive material and are primarily used for aluminum alloy or composite wheels. Adhesive weights are typically lead or steel and are available in standard and low-profile designs. They adhere firmly to the wheel surface, ensuring a secure fit.

Materials Used in Wheel Weights

Steel wheel weights:Steel wheel weights have a relatively low cost and good wear resistance; High strength and hardness; Easy to process and shape, with a wide range of weight options.

Zinc wheel weights:Zinc wheel weights have strong corrosion resistance and moderate density. Has good plasticity and beautiful appearance; High weight accuracy: conducive to achieving more precise wheel balance adjustment.

Lead wheel weights:Lead wheel weights: Lead has a higher density, which means that the required weight can be achieved with a smaller volume, thereby achieving effective balance adjustment in limited space. And it has excellent ductility, easy to process into various shapes and sizes, and can adapt to different installation positions and shapes of wheels. During long-term use, the weight change of lead balance blocks is relatively small, which can maintain a stable balance effect.

Due to its soft nature, it is easier to adhere to the surface of the wheel during installation and secure more firmly.

The Importance of Wheel Weights

Balancing your vehicle’s wheels is important, regardless of vehicle type, for optimal performance, whether it’s a basic SUV or a high-performance sports car. Tire balancing can only be achieved through the use of weights.

The tires on your car are in constant contact with the road surface, making it critical to have properly balanced rims and tires. Adding weights ensures a balanced rotation and enhances braking and maneuverability, particularly on rough terrains.

A vehicle equipped with wheel weights also provides better control on the road. This becomes particularly significant when driving on wet roads, as the presence of weights makes it easier to maintain control of the car.

Regardless of their brand, most wheels have a slight imbalance due to factors such as angular speed, wheel mass and distance from the axis. Adding weights to the wheels helps counterbalance this imbalance.

Whenever new wheels are installed, your auto shop will do what’s called balance and alignment. If you experience vibrations in your vehicle immediately after installing new tires, the technician may not have adequately balanced the wheels. In such cases, it is advisable to return to the installer and have them check the weights on the wheels.

Environmental and Health Considerations

During the use and handling of the wheel weights, there are the following environmental and health precautions:

In terms of environment:

Properly dispose of discarded balance blocks, avoid littering them into the natural environment, and prevent them from becoming solid waste that pollutes soil and water sources.

If the wheel weights involves the use of harmful chemicals in the production process, it should be ensured that the production enterprise emits and treats them in accordance with relevant environmental regulations to reduce pollution to the atmosphere, water, and soil.

In terms of health:

When installing or handling wheel balance weights, operators should wear appropriate protective equipment, such as gloves, to prevent sharp edges or burrs on the metal surface from scratching the skin of the hands.

If the surface of the wheel balance weights is coated or chemically treated, direct contact should be avoided to prevent skin allergies or other adverse reactions.

During the operation, the generated dust may be inhaled, so it is recommended to work in a well ventilated environment or wear a protective mask to protect the health of the respiratory system.

In summary, the use and handling of wheel balance weights need to fully consider environmental and health factors, and comply with relevant regulations and safety operating standards.

Selecting the Right Wheel Weights

1.Vehicle type and model: Different types and models of vehicles have different wheel sizes, weights, and designs, so it is necessary to choose a matching wheel weights.

2.Wheel size and weight: The diameter, width, and weight of the wheel can affect the selection of the wheel weights. Larger and heavier wheels may require larger or more wheel weights to achieve balance.

3.Balance accuracy requirements: Determine the required balance accuracy based on the vehicle’s driving performance requirements and usage environment. For high-speed driving or vehicles with high stability requirements, higher precision balance may be required, which can affect the selection and installation quantity of wheel weights.

4.Material of wheel weights: Common balance block materials include lead, zinc, iron, etc. Lead wheel weights are usually heavy but have a high density, which can provide a good balance effect; Zinc wheel weights are relatively light but also have a certain balance ability; Steel wheel weights may compromise in price and performance. When selecting, it is necessary to consider the characteristics of the material and its impact on the vehicle.

5.Installation method: There are different installation methods for the wheel weights, such as adhesive and clip on. Adhesive wheel weights are suitable for certain specific wheel surfaces, while clip on wheel weights are more suitable for wheels with corresponding mounting structures.

6.Brand and Quality: Choose well-known brands and reliable quality balance blocks to ensure their stable performance, durability, and compliance with relevant standards and specifications.

Installation and Maintenance

Installation:

1.Clean the wheels: Before installing the wheel weight, thoroughly clean the installation area of the wheels to remove dirt, grease, and rust, to ensure that the wheel weights can be firmly attached or clamped.

2.Detection of unbalanced position: Use professional wheel balance detection equipment to determine the unbalanced position of the wheels and the weight of the required wheel weights.

3.Choose the correct position: Based on the detection results, choose the appropriate position to install the wheel weights. Usually, the adhesive wheel weights is pasted on the inner side of the wheel rim, while the clip on wheel weights is clamped on the edge of the wheel rim.

4.Correct installation: The adhesive wheel weights should ensure that the adhesive surface is tightly adhered to the surface of the wheel rim, without bubbles or wrinkles; The clip on type wheel weights should be installed firmly and clamped in place.

Maintain:

1.Regular inspection: It is recommended to regularly check whether the wheel weights is loose, detached, or damaged. Especially after long-distance driving, harsh road conditions, or tire replacement.

2.Rebalance: If any abnormal phenomena such as shaking or deviation are found during driving, it may be a problem with the balance of the wheels. It is necessary to re check and adjust the balance, and replace or reinstall the wheel weights if necessary.

3.Avoiding collisions: In daily use, try to avoid strong collisions or impacts on the wheels to prevent displacement or damage to the wheel weights.

4.Tire maintenance: Maintaining normal tire pressure, regular rotation, and correct installation can help extend the service life of balance weights and maintain the balance of wheels.

Wheel Weights Are Placed Directly on the Wheel

The wheel weights generally cannot be placed directly on the wheel.

The wheel weights needs to be installed in a specific position, usually a designated area on the inner side of the wheel rim. If it is simply placed directly on the wheel without proper balance, it may not be effective and may also shift or fall off when the wheel rotates, causing safety hazards.

The installation of wheel weights requires the use of professional equipment for inspection, to determine the position of imbalance and the weight of the required balance blocks, and then firmly install the wheel weights in the correct position to achieve dynamic balance of the wheels.

Wheel Weights Are Clipped On or Use Adhesive

The use of adhesive or clip on wheel weights depends on various factors.

Adhesive wheel weights are usually suitable for situations where the surface of the wheel rim is relatively flat and smooth. Its advantage is that installation is relatively simple and it is not easy to fall off due to external collisions.

The clip on wheel weights is more suitable for wheels with specific installation structures at the edge of the wheel rim. Its fixing method is more stable and can withstand larger centrifugal forces.

Conclusion

Wheel weights is a component installed on the wheel to adjust the dynamic balance of the wheel. Its main function is to compensate for the uneven distribution of mass generated during the manufacturing and use of wheels, maintain balance during high-speed rotation, reduce vehicle shaking and vibration, improve driving stability and comfort, and reduce wear on tires and vehicle components.

There are usually two installation methods for wheel weights: stick on and clip on. In terms of materials, common ones include lead, zinc, steel, etc. Its weight and installation position are determined based on the imbalance of the wheels and the inspection results.

In the maintenance and upkeep of vehicles, wheel balance detection and adjustment of wheel weights are important links, which help to ensure the good performance and safe driving of the vehicle.

RFQ

1.How do I know if my wheels need balancing?

- Vehicle shaking: When you feel significant shaking in the steering wheel, seats, or body at a specific speed (such as 60-80 km/h), and the shaking decreases or disappears at other speeds, this may be a sign of wheel imbalance.

- Uneven tire wear: Check the tire and if uneven wear such as unilateral wear, blocky wear, or wavy wear is found, it may indicate that the wheel is out of balance.

- Runaway phenomenon: When the vehicle is driving in a straight line, if the steering wheel is not supported, it will automatically deviate and require continuous correction of direction, which may be caused by wheel imbalance.

- Driving experience changes: If you feel that the stability and comfort of the vehicle’s driving have significantly decreased, and the handling is not as flexible as before, it may also be due to issues with wheel balance.

2.Can I install wheel weights myself?

It is not recommended that you install the wheel weight yourself.

Installing wheel balance weights requires professional equipment and skills. Firstly, to accurately detect the imbalance and position of the wheels, a high-precision wheel balancing machine is required. Secondly, during the installation process, it is necessary to ensure that the wheel balance weights is installed in the correct position and firmly adheres or clamps, otherwise it may not achieve good balance effect, and even fall off during driving, causing safety hazards.

In addition, if installed improperly, it may also damage the wheels or affect the normal use of the tires.

So, in order to ensure driving safety and balance, it is best to send the vehicle to a professional car repair shop or tire shop, and have trained professionals install the wheel balance blocks.

3.How often should wheel weights be checked or replaced?

General recommendation: As a general preventive measure, it is also reasonable to check the wheel balance weights every 1-2 years.

The frequency of inspection and replacement of wheel balance weights usually depends on the following factors:

- Mileage and road conditions: If you frequently drive on roads with poor road conditions, such as bumpy or bumpy roads, or have a long driving distance, it is recommended to check the wheel balance weight every 10000 to 20000 kilometers.

- Tire maintenance and replacement: After each tire replacement, repair, or tire rotation, the balance of the wheels should be checked and the wheel balance weights adjusted or replaced as needed.

- Changes in driving experience: If you feel any abnormal conditions such as shaking, deviation, or decreased handling performance of the vehicle while driving, you should check the wheel balance weights in a timely manner.

4.Are there any regulations regarding the use of wheel weights?

Some countries or regions may have lead bans, prohibiting the use of lead wheel weight;For example, some states in the United States have their own lead ban regulations. For example, Washington State passed the HB 1551 Act, which prohibits manufacturers from manufacturing, selling, offering for sale, distributing, or distributing products containing more than 5ppm lead or lead compounds used in Washington State from January 1, 2026. Minnesota in the United States also restricts the use of lead in certain consumer goods.

5.Can unbalanced wheels damage my vehicle?

Unbalanced wheels can damage your vehicle.

Long term use of unbalanced wheels can have various adverse effects on vehicles.

Firstly, it will accelerate tire wear, shorten tire life, and increase the cost of tire replacement.

Secondly, it will cause additional pressure on the vehicle’s suspension system, leading to excessive fatigue of the suspension components, which can easily lead to malfunctions and damage. Furthermore, imbalanced wheels may affect the vehicle’s steering system, leading to increased wear of steering components and affecting handling performance and driving safety.

In addition, long-term imbalance may also have adverse effects on the vehicle’s transmission shaft, wheel hub and other components, increasing maintenance costs. Therefore, maintaining the balance of the wheels is crucial for the normal operation of the vehicle and the lifespan of its components.