Stick on wheel weights supplier & manufacturer

What is stick on wheel weights?

Stick on wheel weight that doesn’t reguire any tools, just peel the back and stick to the rim. The adhesivestyle weight is popular because it can be hidden from view.

Stick on steel wheel weights by Shengshi weigh 0.25oz to 3 oz. eachor 5g to 60g. These weights can be fit to virtually any wheel type for every conceivable wheel balancing application.

Stick on wheel balance weight for different models

Truck Stick on wheel weights

Suitable for trucks, buses, and heavy-duty trucks.

Motorcycle stick on wheel weights

Suitable for motorcycles and small electric vehicles

Regardless of the type of vehicle, these stick on wheel weights are supported by strong adhesive materials and are mainly used for aluminum alloy or composite material wheels. Can be used for standard and low profile designs. They firmly adhere to the surface of the wheels, ensuring a secure installation.

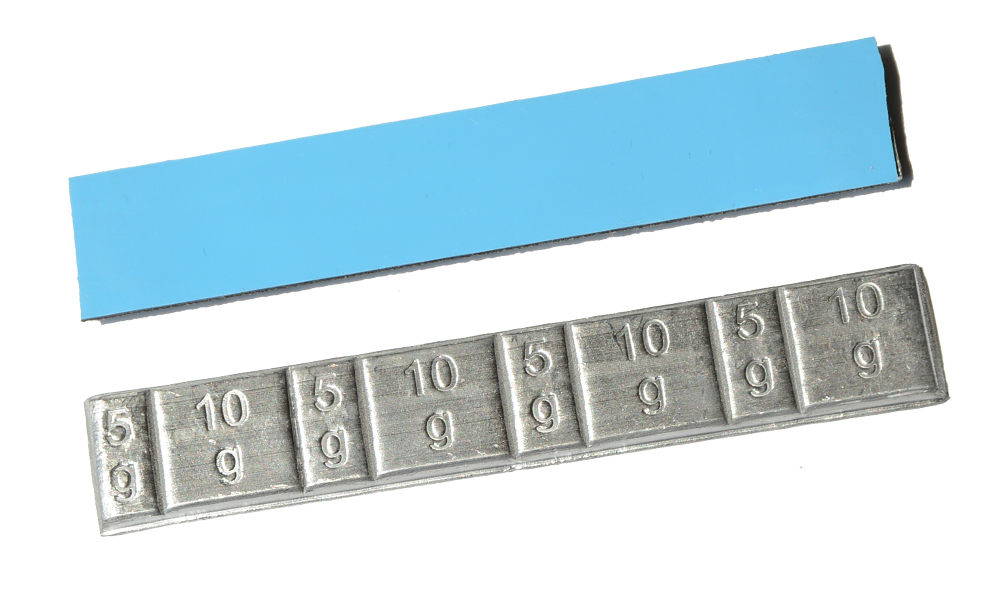

Steel Stick on wheel weights

Competitive price, Environmental protection, anti-rust and anti-corrosion.

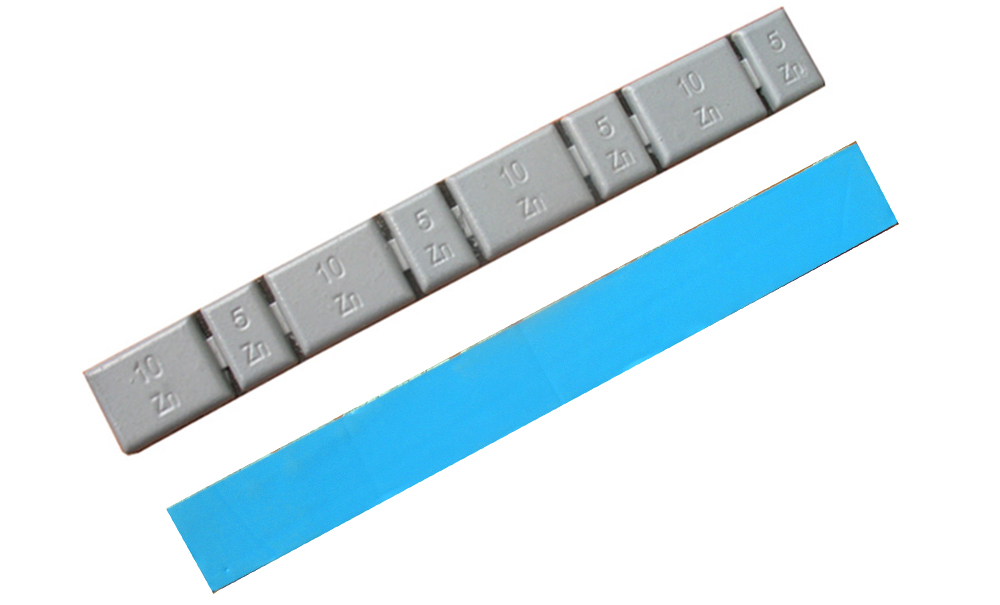

Zinc Stick on wheel weights

Supplied to European, American market, to prevent secondary pollution, more environmentally friendly.

Lead Stick on wheel weights

High softness, and better fit for rims.PB/lead material is the traditional raw material of wheel weight.

Stick on Wheel Weights Tape

We offer 7 types of tape for you to choose from, and you can customize the back adhesive logo.tapes available in regular and easypeel style.

Blue Tape

Red Tape

Paper Tape

3M Tape

Norton Tape

Lohmann Tape

White Tape

Black stick on wheel weights advantages

1.Silver or black powder-coated surface helps eliminate corrosion and staining of expensive wheels

2.Strong adhesive backing for dependable attachment

3.Lead-free, steel construction has less impact on the environment

4.Meets national environmental laws and health and safety codes

5.Designed to have same fit, function & look as OEM weights

6.Narrow profile contours easier to OEM wheel shapes

7.Slender profile and out-of-sight mounting capability enhance the looks of any wheel

8.Low-profile design for increased clearance of close-proximity calipers or brake components

Installation method of stick on wheel weights:

1. Prerequisites:

The surface to attach the adhesive wheel balance weight on the wheel rim must not exceed a maximum slope of 15 degrees of axial direction (hub direction).

The surface energy of the surface to be bonded to the wheel rim must be at least 32 mN/m.

The permissible processing temperature must not be less than 10°C

The wheel rim surface must be free of grease, silicon and dust and be dry.

There must not be any adhesive residues or adhesive tape left on the adhesive surface of the wheel

2. Pre-Treating The Rim:

Clean the rim thoroughly with a cleaning agent that is compatible with varnish.

3. Pre-Bending The Wheel Weight:

Separate the correct gramage (as calculated) from the bar. Mould the shape of the weight to match the rim radius (with protective film).

PLEASE NOTE: You need to bend the weights gradually, otherwise they will break apart at the joins. You should bend the weight to a little more than the rim’s radius.

4. Stickin The Wheel Weight On:

Attach the weight to the calculated point on the rim, making sure that the weight is distributed evenly either side and the weight is parallel with the edge of the rim.

PLEASE NOTE: Press down on the weight hard, working from the centre to the left and right.

The adhesive force of the wheel balance weight strip reaches 80%-90% in about 24 hours, and the adhesive force reaches 100% after 72 hours.

More stick on tire weights information

Advantage of Steel wheel balance weight

Steel Stick on wheel weights are becoming industry standards for health and safety. Although the size of steel counterweights may be larger than that of lead counterweights, steel counterweights have the highest density of cost-effective alternatives with no known environmental or health issues. Materials with lower density, such as zinc, produce longer weights, so that in higher weight increments, the center of gravity of these weights may be below the rim flange, leading to weight chasing and balance accuracy issues. Wheel counterweights made of higher density materials (such as steel) do not have this issue.

Due to improved availability and quality, as well as different pricing levels, Steel wheel weights have become increasingly attractive. Steel stick on wheel weights also have aesthetic advantages, as they typically come in multiple colors and can be integrated with aftermarket wheels. For example, steel black adhesive wheel weights can be used for black painted wheels to blend in color.

Advantage of Lead stick on wheel balance weight

Lead stick on wheel weights have been manufactured for decades and are known to be more malleable and denser than zinc and steel. With greater density, a lead wheel weight allows technicians to install a smaller, yet heavier, weight.

But, depending on where you live, you might not legally be allowed to sell, distribute or service a vehicle with lead wheel weights. According to the EPA and the U.S. Geological Survey, lead weights that fall off vehicles and are ground up on roadways can contaminate water sources. Lead is known to be highly toxic and has been linked to a variety of health hazards.

Advantage of Zinc wheel balance weight

Like lead wheel weight, zinc wheel weight are also cast, providing a more contoured appearance on the wheels. However, their density is also lower, making them larger on the wheels. In addition, its price is also higher than that of iron and lead, and they are more difficult to produce to strict weight tolerances. Currently, an environmental impact assessment is being conducted. There is no recycling plan for zinc wheel weight.