An Introduction to Types of Wheel Balance Weights (Practical Guide 2026)

Wheel balance weights are crucial components for ensuring smooth vehicle operation, reducing tire wear, and minimizing steering wheel vibration. Based on their installation method and material, the main types currently available on the market are as follows:

I. Classification by Installation Method

- Features: Secured to the outer edge of the wheel hub (steel or aluminum alloy rim) using metal clips, and installed by tapping with a special balancing pliers.

- Common Clip Types:

- MC: Suitable for mainstream North American aluminum alloy wheels (Ford, General Motors, Stellantis, etc.)

- AW: Suitable for European wheels (Volkswagen, BMW, Mercedes-Benz, etc.)

- P: Used for ordinary steel wheels

- FN: Dedicated for Japanese and Korean models (Toyota, Honda, Hyundai, etc.) Advantages: Fast installation, low cost, easy removal.)

Note: Must match the wheel rim profile, otherwise it is prone to falling off.

✅ Applicable Scenarios: Routine wheel balancing operations in 4S dealerships, tire shops, and repair shops.

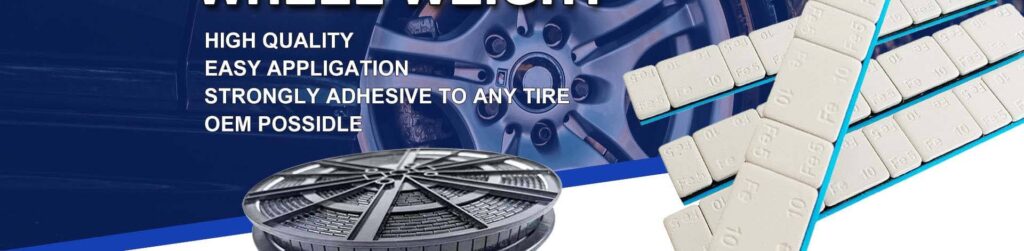

- Features: Equipped with high-performance pressure-sensitive adhesive on the back, for direct application to the inner surface of the wheel rim (typically the inner wall of aluminum alloy rims).

- Also known as: Painted balance weights, self-adhesive balance weights (because they are often used on painted wheel rims to avoid scratching the surface)

- Advantage:

- Does not damage the wheel rim’s appearance (no clamps, no hammering)

- Suitable for high-end wheel rims with no outer lip or deep recess design.

- Key requirements: The bonding surface must be clean, dry, and oil-free, and the weight must be pressed firmly into place.

✅ Applicable Scenarios: High-end vehicles, custom wheels, aftermarket repair and maintenance market

II. Classification by Material

1. Steel Wheel Balance Weights (Fe)

- Main component: Low-carbon steel (with anti-corrosion coating)

- Advantages: Low cost, high strength, environmentally friendly (lead-free), complies with RoHS/EPA standards

- Current status: Has become the mainstream alternative globally, especially mandatory in European and American markets.

2. Zinc Wheely Balance Weights (Zn)

- Main component: High-purity zinc

- Advantage:

- High density (heavier than iron, allowing for large counterweights in a small volume)

- Strong corrosion resistance

- Smooth surface, suitable for high-end applications

- Disadvantage: Slightly higher cost than iron-based weights.

3. Lead Wheel Balance Weights (Pb) (⚠️ Gradually being phased out)

- Previously widely used due to their high density and ease of processing.

- Current situation: Due to heavy metal pollution, their use in the automotive industry has been banned or restricted in many countries, including the EU, the United States, and China.

🌍 Trend: Lead-free (Fe/Zn) is a globally mandated direction.

III. How to Choose the Right Wheel Balance Weights?

| Wheel Hub Types | Recommended type | Material recommendations |

| Ordinary steel ring | Clip-on type (P-type) | Fe or Zn |

| American-made aluminum alloy wheels | Snap-on type (MC type | Fe-MC / Zn-MC |

| European-style aluminum alloy wheels | Clip-on type (AW type) or adhesive type | Zn-AW / Stick-on Zn |

| Japanese and Korean Wheel Rims | Clip-on type (FN type) | Fe-FN |

| High-end/Custom Wheels | Stick-on | Stick-on Zn |

IV. Future Trends

- ✅ Completely Lead-Free: Iron (Fe) and Zinc (Zn) Become the Standard

- ✅ Precise Light weighting: Small-sized, high-density balance weights reduce the load on the wheel hub.

- ✅ Intelligent Matching: Some devices support scanning QR codes to identify wheel rim models and automatically recommend the appropriate balance weight type.

Friendly reminder: Regardless of the type, correct installation + matching the wheel rim = safe and smooth driving. Do not mix clip types or apply to dirty surfaces!