How much do you know about the two types of wheel weight, spray wheel weight and galvanized wheel weight?

At present, there are two surface treatment methods for mainstream wheel weight on the market, spray wheel weight and galvanized wheel weight. What is the difference between these two surface treatments? Here we will introduce them in detail.

Operation process

1. Spray treatment

Through electrostatic spraying, the paint is sprayed evenly on the surface of the object in the form of mist using a spray gun. After the paint contacts the surface of the object, it is heated and dried to dry and solidify the coating. A layer of coating with specific properties is formed on the surface of the wheel weight.

2. Electrogalvanizing Electrogalvanizing is to reduce and deposit zinc ions on the metal surface to form a coating in an electrolyte containing zinc ions through the action of direct current. .

Difference

①. Appearance

lSpray wheel weight: usually the surface is smoother, and there are generally more colors. Common colors are black and gray. Colors can also be customized according to customer needs, such as red, yellow, blue, white, etc.

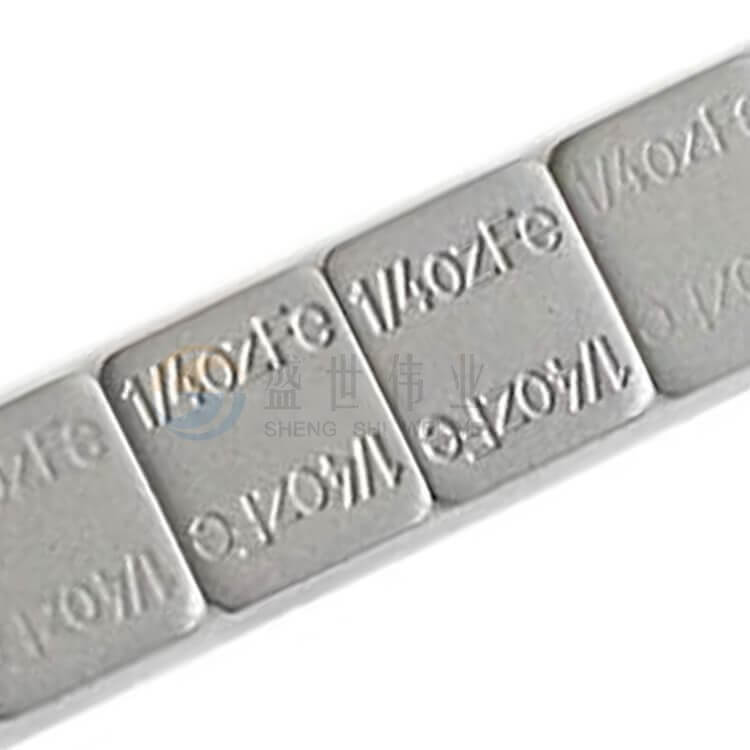

l Galvanized wheel weight: bright appearance, metallic texture, and generally single color.

②. Corrosion resistance

l Spraying wheel weight: The corrosion resistance of the coating is relatively strong. In harsh environments, such as humid and high-salt environments, it is not easy for the coating to fall off or rust.

l Galvanized wheel weight: Generally has good corrosion resistance and can maintain stability for a long time in harsh environments.

③. Bonding strength

l Spraying wheel weight: The bonding strength between the coating and the balance block substrate is relatively tight. When subjected to external impact or friction, the coating is not easy to peel off.

l Galvanized wheel weight: The bonding between the electroplating layer and the substrate is relatively tight, the bonding strength is high, and it is not easy to peel off.

④. Cost

l Spraying wheel weight: The production cost is high. Spraying treatment is carried out on the basis of electroplating. The process is complicated and requires professional equipment and technology. At the same time, environmental protection measures such as wastewater treatment are also required.

l Galvanized wheel weight: The production cost is relatively low, mainly because the operation process is relatively simple and the equipment investment is small.

2. Advantages

Advantages of spraying wheel weight

Wide applicability: It can be sprayed according to different needs to meet the requirements of different colors and logos.

Good corrosion resistance: suitable for various harsh environments and can maintain long-term stability.

High bonding strength: not easy to peel off and long service life

Advantages of galvanized wheel weights

Low price: for some cost-sensitive users, galvanized balance weights are a more economical choice.

Beautiful appearance: with good metallic luster, it can improve the appearance quality of the product.

High bonding strength: not easy to peel off and long service life.