OEM wheel weight specifications

Classification by weight

Common ones are 5g, 10g, 15g, 20g, 25g, 30g, 35g, 40g, 45g, 50g, 100g, 150g, etc. Different models and wheel sizes have different requirements for the weight of the balance weight. Small cars generally use 5g-50g balance weights, while large vehicles such as trucks and buses may use 50g-500g wheel balance weights.

Classification by shape

Adhesive wheel weight: usually long strip or rectangular, with strong glue on the back, can be directly attached to the inside of the wheel hub. Its thickness is relatively thin, generally around 2mm-5mm, with different lengths of 20mm, 30mm, 40mm, etc., and the width is between 10mm-20mm.

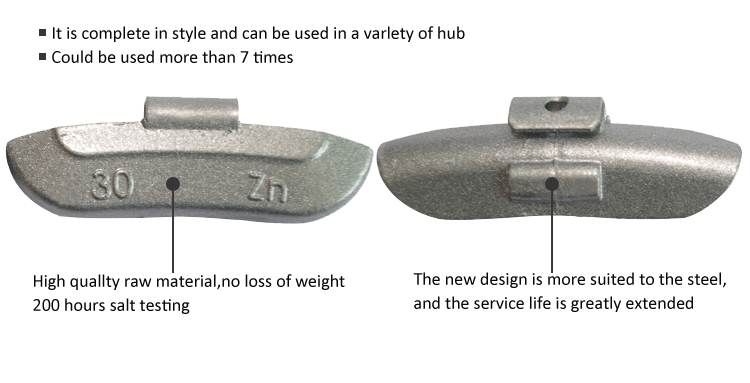

Clip on wheel weight: has a hook structure that can be stuck on the edge of the wheel hub. The shape is similar to “L” or “Z”, and the length and width of the hook part will be designed according to the size of the wheel hub edge. Generally, the length of the hook is 10mm-15mm, the width is 5mm-8mm, and the size of the main part is similar to the adhesive wheel weight.

Classification by applicable models

Wheel weight for cars: generally lighter in weight to adapt to the characteristics of small wheels and high speed of cars. Common car wheel balance weights weigh between 5g-25g per piece.

Wheel weights for light trucks and buses: They are relatively heavy, generally between 25g and 100g, to meet the vehicle’s larger load and driving requirements.

Balance weights for heavy trucks and engineering vehicles: They are heavier, up to 100g-500g, to meet the needs of balancing large-sized and high-load wheels.