Wheel Alignment For Truck supplier & manufacturer

Wheel Alignment For Truck

Reliable wheel alignment equipment and machines for professional garages.

Specifications

- 5D High Precision Camera Assemblies ———————————– 2PCS)

- Manual Type Lifting Column ———————————————– 2PCS

- Target ————————————————————————– 6PCS

- Target ————————————————————————— 8PCS (Optional)

- Clamp ————————————————————————— 3 pairs

- Inside-Hole Clamp ———————————————————– 1 pair

- Ultra-thin Turntable ——————————————————— 1 pair

- High quality miniature Lenovo computer —————————— 1set

- Mobile type power supply ———————————————— 1PCS

- Fashion Cabinet ————————————————————- 1set

- Power outlet —————————————————————— 1PCS

| Technical Parameter | ||

| Measurement Item | Accuracy | Measurement Range |

| Display Accuracy | 1’/0.01°/0.1mm | |

| Camber | ±2 | ±10° |

| Caster | ±2 | ±20° |

| King-pin | ±6 | ±20° |

| Wheel Toe | ±2 | ±20° |

| Set Back | ±2 | ±5° |

| Thrust angle | ±2 | ±5° |

| Track Width | ±2mm | 1100-2600mm |

| Wheelbase | ±2mm | 2000-15000mm |

| Trailers | ±2mm | 2000-15000mm |

| Max-turn | 0.05° | ±50° |

Features

- Wide-angle lens: 5D cart positioning is the world’s first combination of multi-axle cart and 5D technology, first to achieve full-bridge, half-bridge, multi-axis head and trailer for a comprehensive measurement;

- The positioning of the cart requires eccentric compensation. The multi-wheel multi-axle car takes 15 minutes, and the 5D cart positioning can be compensated by pushing the car or two points to achieve the 20S measurement.

- 3. 5D cart positioning can simultaneously measure multiple axes, breaking through the troubles of traditional cart positioning and replacing sensors, and the efficiency is greatly improved;

- Convenient maintenance: maintenance and calibration is extremely convenient. Just send the camera back, save time and trouble, and ask about the troubles of beam transportation;

- The size of the car is compatible: from the truck to the small car, the new 3D solves the problem of multiple parking spaces;

- Free calibration: the expression has been accurate at the factory, and can be installed and used at the scene;

- Automatic tracking system: 5D automatic tracking system, according to the body, the target height, automatically adjust the height of the head kit, to ensure that the camera, target target measurement system is always in the best measurement state, to ensure the accuracy of measurement results, and further improve users Detection; (optional

- Optional high-efficiency three-jaw fixture for quick clamping; (optional)

- It realizes independent mobile design through wireless transmission, which is more convenient to use. (optional)

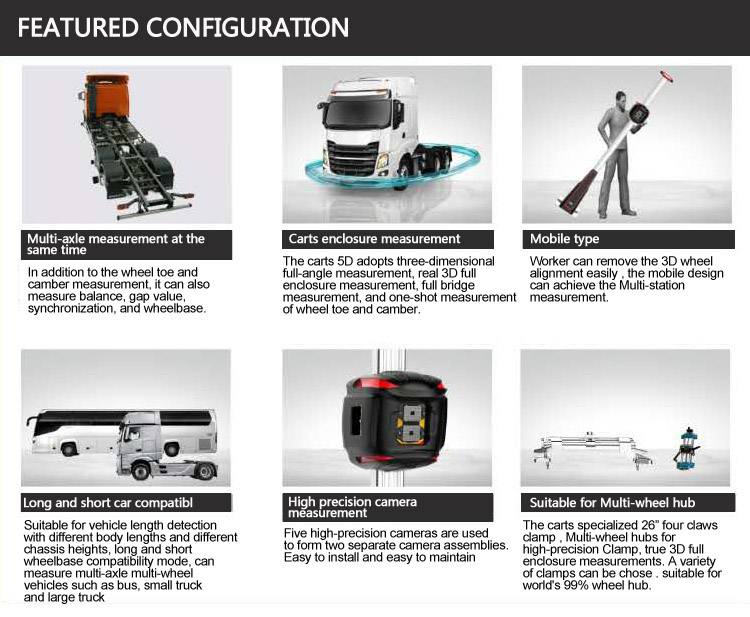

Featured configuration

Multi-axle measurement at the same time . In addition to the wheel toe and camber measurement, it can also measure balance, gap value, synchronization, and wheelbase.

Carts enclosure measurement The carts 5D adopts three-dimensional full-angle measurement, real 3D full enclosure measurement, full bridge measurement, and one-shot measurement of wheel toe and camber.

Mobile type Worker can remove the 3D wheel alignment easily , the mobile design can achieve the Multi-station measurement.

Long and short car compatible Suitable for vehicle length detection with different body lengths and different chassis heights, long and short wheelbase compatibility mode, can measure multi-axle multi-wheel vehicles such as bus, small truck and large truck

High precision camera measurement Five high-precision cameras are used to form two separate camera assemblies. Easy to install and easy to maintain

Suitable for Multi-wheel hub The carts specialized 26” four claws clamp , Multi-wheel hubs for high-precision Clamp, true 3D full enclosure measurements. A variety of clamps can be chose . suitable for world’s 99% wheel hub.

Time efficiency is significantly improved

There is no need to make four-wheel single-wheel compensation. It takes about 5 minutes for different 2D positioning, and only 30 seconds for 5D multi-axis positioning, which greatly improves the efficiency.

Stability is greatly improved

The influence of sunlight is greatly reduced. The light of ordinary equipment is very easy to affect the reception error. The target of the electronic original is replaced, and the sensor is replaced, and the failure rate is greatly reduced. The sensor does not need to be charged, and it also reduces the battery failure rate.

Higher precision and wider measurement range

The body plane is established by three-dimensional coordinates, the more advanced compensation mode reduces errors, and the finer image capture technology is more accurate than the traditional line array measurement mode.

Product LIst

Contact Us

Tel:+86-18713779288 Email:wheelweight9@ssqcpj.com